Aug 2,2023

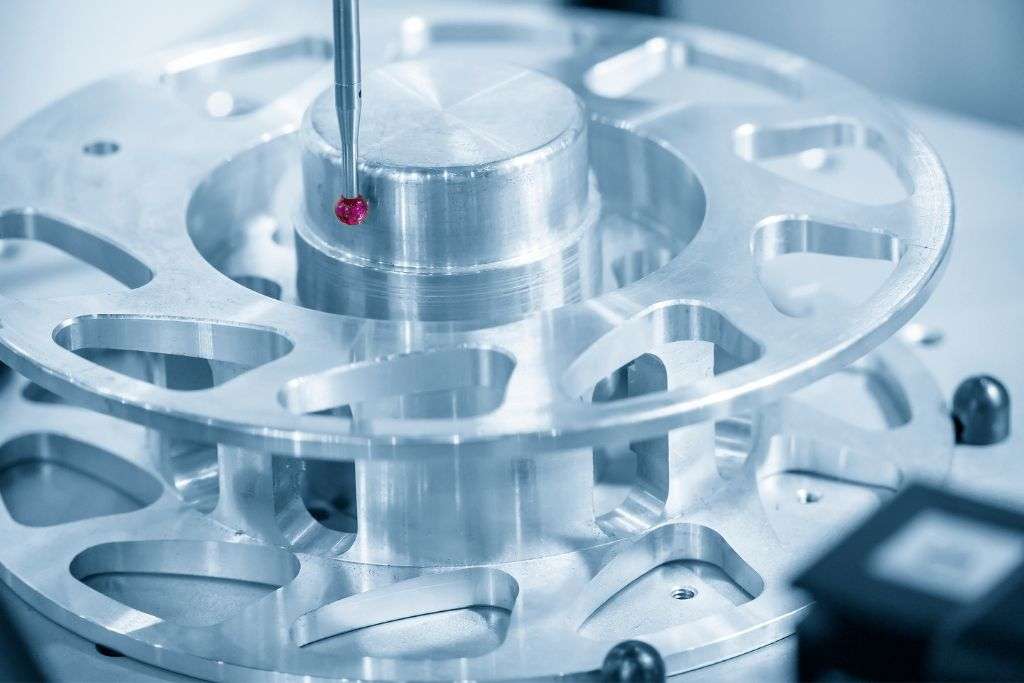

Precision machining is a procedure that manufacturers employ to remove excessive raw material from a part while holding close tolerance finishings to develop a completed product. Simply, it means shaping a material’s huge pieces into more precise components to ensure they meet exact specifications. This procedure involves turning, milling, electrical discharge machining, and cutting. Manufacturers usually use computerized numerical control machines to perform this precision machining.

Precision machining ensures that manufacturers produce both small and large products that people use in their daily lives. This blog section discusses the reasons behind choosing aluminum parts for precision applications encouraging you to buy these parts from a well-reputed bulk aluminum machined parts dealer.

Machined aluminum parts allow manufacturers to carry out precision manufacturing that ensures they make components with high accuracy and tolerances. By employing technologies like computerized numerical control machining and three-dimensional printing, makers can achieve exact results that are tough to attain with conventional production methods.

The precision here means that manufacturers can use the products made from machined aluminum parts in different applications where accuracy is essential, like automotive, medical, and aerospace industries.

Manufacturers can quickly machine aluminum, which tells us they can precisely shape and form it to meet specifications. This is necessary for applications where tight tolerances are needed. Aluminum features very high dimensional stability. Thus, machinists could cut away from this metal and keep residual stress in check.

Using advanced coolants and carbide tooling, manufacturers can use machined aluminum components to make products with excellent finishing and bead blast them for a matt finish.

They can anodize these components for constant aesthetic finishing and equip them with the ability to offer extra corrosion resistance. In this manner, manufacturers can produce precise products with machined aluminum components.

Manufacturers can make machined aluminum components to exact dimensions, essential for applications where accuracy is important.

Ideal Strength to Weight Ratio

The weight of aluminum is lower than that of other metals, so if manufacturers are interested in cutting, it is an excellent option. Whereas pure aluminum’s tensile strength is lesser than one hundred megapascals, it could be hardened as follows.

Alloying, mixing aluminum with other elements enhances its grain structure.

Heat treatment, heating aluminum, and then cooling this metal at a particular rate to develop ideally sized crystals.

Work hardening, intentionally deforming aluminum to change its grain structure. Manufacturers usually do this through heat treating (rolling, for instance, could be done after forging).

A temper designation shows the strength or precise condition of the resulting substance. T for thermal and H for hardened.

Here, several aluminum alloys have a greater strength-to-weight ratio, or particular strength, than stainless steel, three hundred and sixteen L.

Whereas corrosion resistance would differ between grades, aluminum is an ideal choice for manufacturers who need to make highly corrosion-resistant metals. This metal and its composites feature a great affinity for oxygen metals that are very reactive such as magnesium will oxidize simply, whereas less reactive metals develop a loose oxide layer like rust on steel and iron.

Contrary to that, when manufacturers expose aluminum, it develops a passivating aluminum oxide layer that seals the surface averting further erosion and oxidation. This coating is self-repairing even if people scratch it. Thus, aluminum might not need surface treatments or painting, providing you with a cost saving on lifetime service and production costs.

In fact, as aluminum is such an ideal material to work with, there are many composites available, each of which has different qualities and applications to meet their needs. Here are some of the very popular grades of aluminum.

This grade of aluminum has high fatigue strength; it trades final tensile strength for greater toughness or ductility after manufacturers alloy it with copper.

Marine grade with great corrosion resistance because it contains high magnesium content.

This grade of aluminum has a nice blend of corrosion resistance, ductility, and strength which have made it versatile. Manufacturers often use this type of aluminum. They produce this grade of aluminum by alloying this metal with a mixture of silicon and magnesium( it is almost equal to six thousand and sixty-one).

Whereas manufacturers often use copper for electrical conductivity, they also use aluminum to make electrical components because it is much lighter and affordable.

In fact, manufacturers use it to make connectors, battery cables, and busbars, especially in electric vehicle and automotive applications. Its nice thermal conductivity also ensures that manufacturers use it to dissipate heat.

People keep sustainability high in their agendas. Therefore, three-fourths of the aluminum produced is yet in use. Recycling aluminum utilizes less power than making it, and as long as manufacturers can keep their impurities in check, they can reuse aluminum.

Cost Savings

Whereas machining needs specialized expertise and machine, it provides many benefits over conventional production procedures regarding cost savings. For instance, machined aluminum composites often need lesser raw materials than other materials such as wood or steel, which enables manufacturers to significantly cut down material costs.

Apart from that, as computerized numerical control machines can operate at a faster speed than conventional manufacturing processes, they also need less labor time- leading to decreased labor costs. Ultimately, machined parts often need less post-processing than those manufactured using traditional procedures. This helps in reducing overall manufacturing costs even further.

Aerospace

Customized machined aluminum parts can handle extreme stresses and presses that a plane experiences at high altitudes without suffering because they do not lose their structural integrity.

By choosing aluminum machined parts instead of steel, engineering professionals can drastically decrease the plane’s weight, thereby improving fuel efficiency and increasing the number of passengers or the level of load a plane could efficiently carry.

Manufacturers use aluminum to produce a broad range of telecommunication components, encompassing heat sink housings, cavities, and covers. Telecom cavities need a great degree of precision, which manufacturers could achieve by machining aluminum.