Aug 11,2023

Behind the word automation, there is a brief concept that is involved as it is more than just a buzzword. It is a type of approach that could be used to manufacture the potential to radically and irrevocably in order to change the trajectory of the business, as, with the potential, the increasing level of automation requires increasingly radical changes for the process of manufacturing.

If it is done in an incorrect manner or at the wrong time, these are the changes that can even derail a momentum of a company. Thus, it is suggested that one should think about the automation strategy in advance, prior to the implementation, in order to ensure success. There are certain things that are helpful in a way that they can help you change the overall approach to automation, providing you with a complete framework that would allow you to automate the CNC machine.

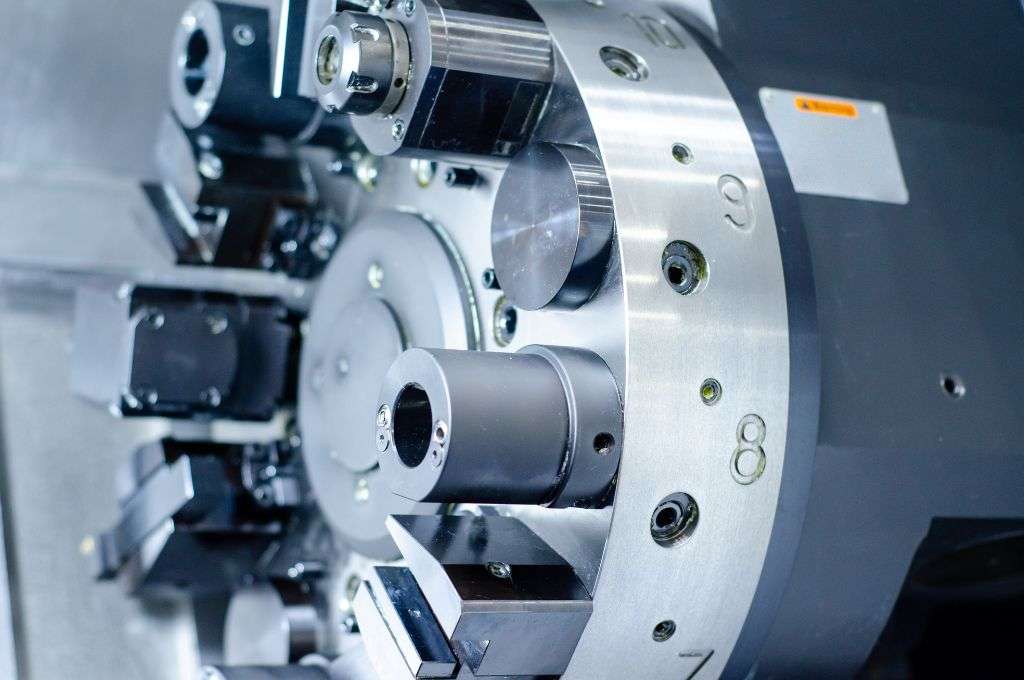

If we think of limiting our discussion to metalworking and machining applications, then immediately as the concept of automation starts appearing as a great idea with very few downsides. In order to upgrade the machining tools to the sophisticated type of CNC, pieces of equipment that are helpful for automation can be very expensive. But with the availability of the latest techniques, there could be seen a wide use of automation in companies allowing us to see increasing automation as a type of process that is changing the dynamics of the market. For example, Automatic metal turning becomes a type of response to external factors rather than a goal on itself. Thus, the approach is considered to be inherently reactive rather than proactive.

Although the reaction produced is not something bad, but it does affect the overall approach, and it changes it as well. however, imagining full automation is the end goal that requires an approach that is far more detailed and comprehensible than anything else. Above that, it also requires envisioning a process that is fully automated and ahead of time. There are various other works and processes that are involved in order to outline a long-term plan to implement complete automation. These processes are comparatively expensive as well. Considering a proactive approach that is to develop automation. This is the ideal approach that reduces the chances of critical errors, errors in the manufacturing process, and the expenses that run overboard.

Automating the machining processes is simply about letting a CNC machine execute a program in the shortest time. In the case of small CNC machining operations, there is a chance that the machine might choose overnight operations in order to extend the working hours, but these sorts of practices are not so beneficial in a way that they are not providing a complete benefit. In the case of complete automation, there is a requirement for the CNC machines not just in the form of one lengthy operation but in the form of a series of operations in one or more parts. there are various machine shops that are waiting for the opportunity so they can attain a level of automation. That requires the control of both the process of production and the environment. This also means that there needs to be control over thermal build-up. In the case of operations that last for longer hours, there are chances of a generation of a significant amount of heat which is usually enough to affect the accuracy of the machine and to change the dimensions of the materials that are being machined. In the case when manual tools are being used, we get to see that it is easier for machine operators to adjust those changes during the operation. However, in the case of an entirely closed-loop system, it becomes a difficult task to minimize the challenges and changes. Thus, it eliminating the need to compensate.

This is the point where the consideration for how to automate your CNC machine transition from general to highly specific. A few examples of these scientific considerations are as follows:

1. Measuring and accounting for the condition of the cutting tool before machining at every step of the process

2. Measuring and accounting for the condition of the cutting tool after every step of the machining process.

3. Having the ability to change out cutting tools or to duplicate them in case a certain type of tolerance is not met.

4. The degree of flexibility that is built into the form of a CNC machine does the machine offers to select the program or not, and the parts that could be chosen from that are unable to machine a single part due to the tool break, switching to another program without any interruption.