Aug 3,2023

Spending some time in the metal parts industry makes you realize a huge change in a few years. Less laborers, more machines, and faster production time are the major elements that need the spotlight.

How come a manufacturer produces thousands of custom CNC parts in a short time? What is transforming this whole industry so fast, which is also expanding the competition and market size? Those machines are CNC machines, which are letting more players enter the industry with better ideas.

Affordable CNC machines and raw materials are allowing manufacturers of different types to capture the market in the most optimized way. This includes all the below factors, which are contributing to the success of customization.

It is not an era where limited designs have to be followed on the availability of working tools and die. Instead, it is an era where CNC machines can turn any design into a physical form.

Any professional operator can design custom CNC parts and then let the machine work on them. You can manufacture automobile parts, tools, surgical instruments, or whatever you want. As technology is upgrading so fast, customization options are also expanding.

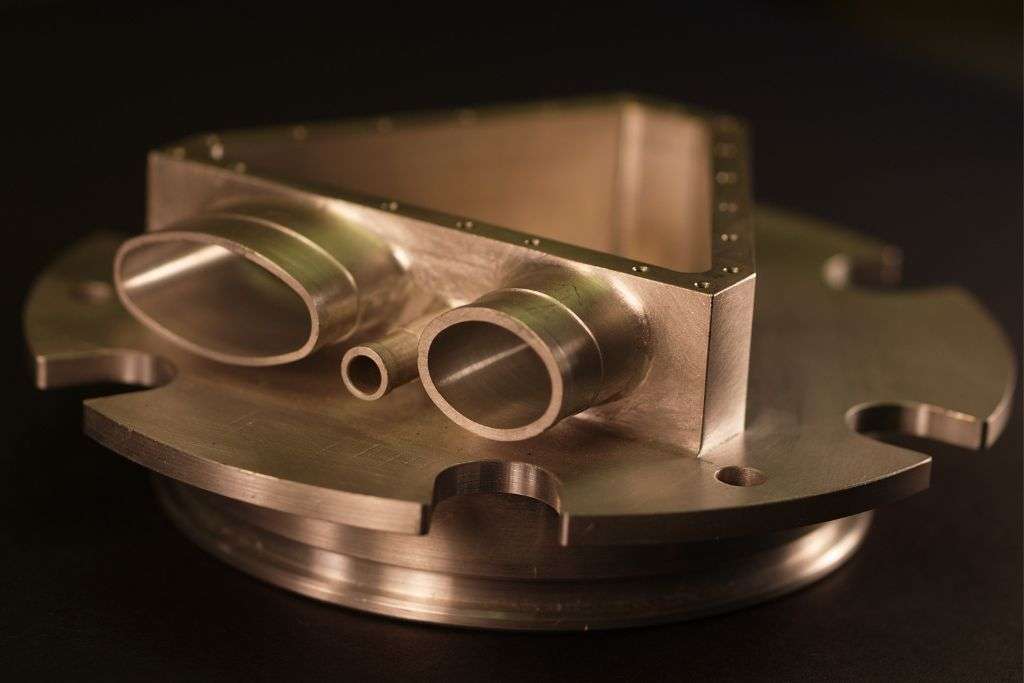

Single and multiple-dimensional operations make any design possible to be processed. Also, multiple metals are workable because of the compatibility of working tools’ strength. Stainless steel, copper, titanium, carbon steel, and every other metal is workable on CNC machines. Hence, it does not take much time for a manufacturer to manufacture metal parts in any shape.

Likewise, manufacturers are not restricted to any specific list of designs. They can convert any digital design into reality with the help of customizations. All a buyer has to do is provide their desired shape and design.

There is hardly any shape that can not be processed by CNC machines. Due to their multidimensional work, they analyze the workpiece and act accordingly.

In addition, CNC machines are becoming faster and more compact for more customization. You can work on the thickness level of custom parts’ walls. Likewise, a high tolerance level makes for better customization of custom parts.

This transformation helps manufacturers produce compact parts, which can’t be made with the help of die-casting methods. Where other methods can not do the job, CNC machines show unbelievable results.

Likewise, high tolerance comes through the rapid movement of working tools. This movement is controlled with the help of coding in the CNC machine.

This adds up to more benefits to custom production because buyers can choose what kind of part they need. Smaller parts need more tolerance, and vice versa.

Who doesn’t want fast production and low lead time? It is an objective of all manufacturers, especially in this modern age. They use state-of-the-art machines to meet massive targets.

Custom CNC parts are the result of that fast production. It was not possible in the past the way it has become now. As high growth took place in the industry, cheaper production started to take place.

CNC machines can outperform many traditional modes in terms of production speed. When manufacturers go for large volume production, they get lower lead time.

That means the customers do not have to wait as much as they had to wait in the past. A single CNC machine can work on a workpiece much faster than traditional machines. That saves time and energy for the machine to complete orders earlier.

Manufacturers have got more freedom of production than before. But in what ways? In customization of shape, size, weight, metal type, and other factors. Now, manufacturers have options to choose any metal from a wide range, as they have better working tools.

Also, the cutting speed of the tool helps them get sharper results from custom CNC parts. To illustrate, an engine body can be manufactured by CNC machines much better than old methods.

They can work on a larger area with the help of a higher tool path and its multidimensional working. It means they will have fewer limitations in producing more complex parts. The complexity will not be a hurdle in their path for modern machines.

Many new machine parts are different from the traditional ones, which need CNC customization for production. It is not possible for a manufacturer to instantly change the template of a machine. However, CNC machines allow high flexibility in working.

All the bulk manufacturers want to work on economies of scale. It is possible only through some specific modes. CNC customer parts production depends on the type of machines a manufacturer uses. To achieve that massive production scale, they have to use faster and larger machines.

However, the cost of production of custom CNC parts reduces as the production size increases. This is a common way of meeting cost-friendly production. This low-cost production leads to lower prices of custom parts. Then the betterment takes place not only in production but also in price.

The last is about automation, which is the talk of the town nowadays. Machines are replacing humans much faster than before.

CNC machines are among them, which have reduced the need for laborers in the past few years. This high automation is the biggest reason for the custom CNC parts transformation. In this way, all the manufacturers give tough competition to each other.

This entire industry is evolving so fast with high-tech machines like CNC machines. They need some instructions through codes, and you can get any productive result from them.

There is no chance anyone would go for traditional modes of production amid the CNC machines’ rise. In just a blink of an eye, you can get a better-quality CNC custom part instantly.

You might be wondering how easy it has become for the manufacturers to transform the digital form into the physical custom part. This is all about the right technology and the right tapping of the market.